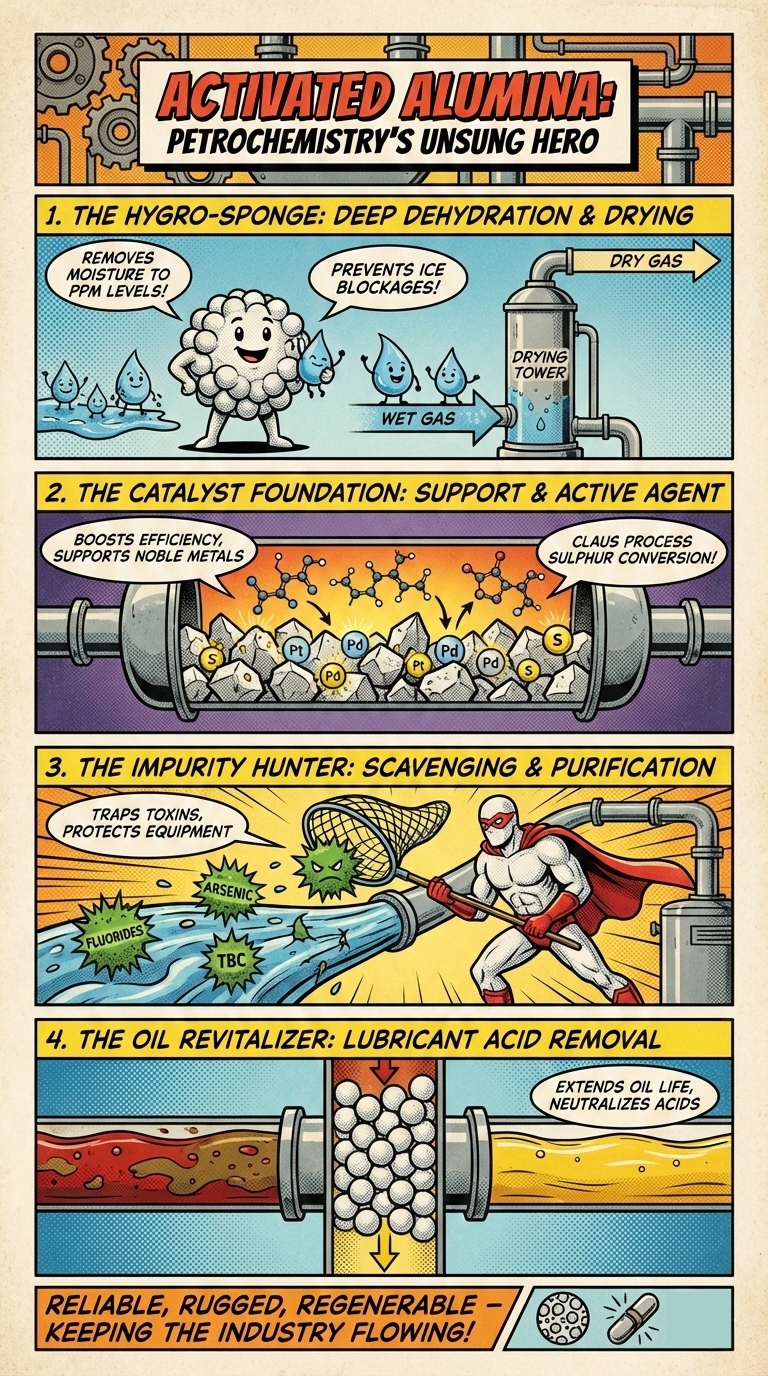

1. Deep Dehydration and Drying (High-Efficiency "Sponge")

In petrochemical production, water is the "nemesis" of many reactions. Activated alumina is widely used for deep drying of both gas and liquid phases: Cracking gas drying: In the production of ethylene and propylene, water must be reduced to extremely low levels (even below 1 ppm) using activated alumina dryers to prevent ice formation and equipment blockage during low-temperature separation processes. Liquid hydrocarbon dehydration: For example, the dehydration of liquefied petroleum gas (LPG) or alkane streams.

2. Catalyst and Catalyst Support ("Solid Stage")

Activated alumina is not just a supporting player; it often directly participates in reactions or provides support for expensive precious metals: Catalyst support: It is often used as a support for active components (such as platinum, palladium, and molybdenum) in hydrodesulfurization, hydrorefining, and reforming reactions. It allows for uniform distribution of active components, improving catalytic efficiency. Claus catalyst: In refinery sulfur recovery units, activated alumina is the main catalyst for the Claus reaction, converting highly toxic hydrogen sulfide (H₂S) into elemental sulfur, protecting the environment.

3. Impurity Removal and Purification ("Loyal Guardian")

Petrochemical raw materials often contain trace amounts of harmful impurities, and activated alumina can precisely "capture" them.